¿¿ para qué se utilizan los productos de película pet?

24 de julio de 2023|

24 de julio de 2023| Vista: 240

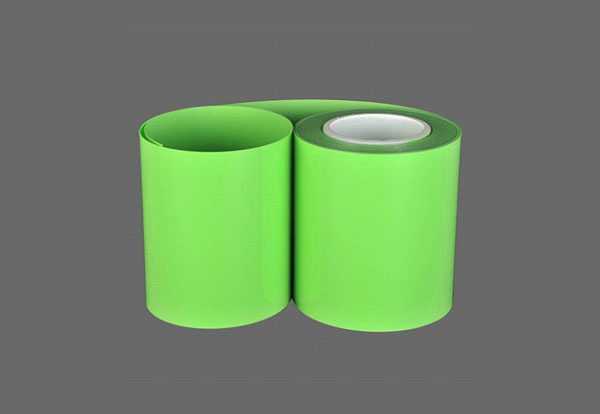

Vista: 240Los productos de película PET son un material ampliamente utilizado y ampliamente utilizado. El PET o el tereftalato de polietileno es un plástico sólido, flexible y transparente utilizado en la fabricación de diversas películas, incluidos materiales de embalaje, películas protectoras y películas de visualización.

En nuestra empresa ofrecemos una serie de productos de alta calidadProductos de película PETEstá diseñado para satisfacer las necesidades de nuestros clientes. Nuestros productos son conocidos por su durabilidad, flexibilidad y Alto rendimiento, y son ideales para una variedad de aplicaciones.

1. ventajas de los productos de película PET

Una de las principales ventajas de los productos de película PET es su versatilidad.Película PETProductosSe pueden fabricar productos de todo tipo de espesor, anchura y longitud, adecuados para todos los campos, desde envases de alimentos hasta aplicaciones industriales. También son conocidos por su excelente resistencia a la humedad, resistencia a los productos químicos y radiación ultravioleta, y son ideales para productos que requieren alta protección y durabilidad.

Hay varios tipos de productos de película PET disponibles, cada uno de los cuales tiene sus propias propiedades y aplicaciones únicas. Algunos de los tipos de películas PET más comunes incluyen:

Película de embalaje - para el embalaje de alimentos, bebidas y otros bienes de consumo.

Película protectora - utilizada para proteger la superficie de arañazos, desgaste y otros daños.

Película de visualización - para pantallas electrónicas, pantallas táctiles y otras aplicaciones que requieren alta definición y resolución.

Película laminada - para laminar materiales juntos para aumentar la resistencia y la durabilidad.

Película de desmoldeo - para desmoldear adhesivos y otros materiales del soporte.

2. aplicación de productos de película PET

Los productos de película PET son ampliamente utilizados y ampliamente utilizados. Algunas de las aplicaciones más comunes de los productos de película PET incluyen:

Las películas de embalaje - PET se utilizan generalmente en envases de alimentos, envases de bebidas y otros bienes de consumo.

Aplicaciones industriales - las películas PET se utilizan en diversas aplicaciones industriales, incluyendo aislamiento, componentes eléctricos y piezas de automóviles.

Las películas de visualización - PET se utilizan en pantallas electrónicas, pantallas táctiles y otras aplicaciones que requieren alta definición y resolución.

Etiquetas y pegatinas - las películas PET se utilizan generalmente en etiquetas de productos, pegatinas y otros materiales de marca.

La película protectora - película PET se utiliza para proteger la superficie de arañazos, desgaste y otros daños.

3. precauciones para personalizar los productos de película PET

Cuando se trata de productos de película PET personalizados, hay varios factores a tener en cuenta.

Estos incluyen el tipo y grosor de la película, el nivel de protección requerido y los requisitos de aplicación. Trabajar con proveedores experimentados es fundamental para garantizar que la película satisfaga sus necesidades y requisitos específicos.

4. Resumen

En resumen, los productos de película PET ofrecen una serie de beneficios y aplicaciones en diversas industrias. Desde envases y etiquetas hasta aplicaciones y presentaciones industriales, los productos de película PET son un material multifuncional y de alto rendimiento que se puede personalizar en función de su proyecto específico. Póngase en contacto con nosotros de inmediato para obtener más información sobre nuestros productos de película PET y cómo le ayudamos a lograr sus objetivos.